The ultra-high pressure (UHP) jetting system, which powers the water jet to over the speed of sound, was deployed without the foundation touchable in the pipe proved too tough for conventional robotic cutting.

The only practical volitional would have been to excavate and replace the pipe, veiled three metres underneath extensions built overdue the row of nine terraces homes in Ilford, north east London.

That would have involved the extensions for three of the homes stuff all but demolished, then reinstated, with the occupants placed in temporary walk-up while the work was done.

Lanes carried out the UHP jetting project on behalf of Thames Water and has now used the technique to well-constructed other challenging touchable removal projects for the water company.

Lanes Operations Manager Calvin May said: “This was one of the toughest touchable removal projects we’ve overly tackled, and involved contamination of a 150mm-diameter sewer.

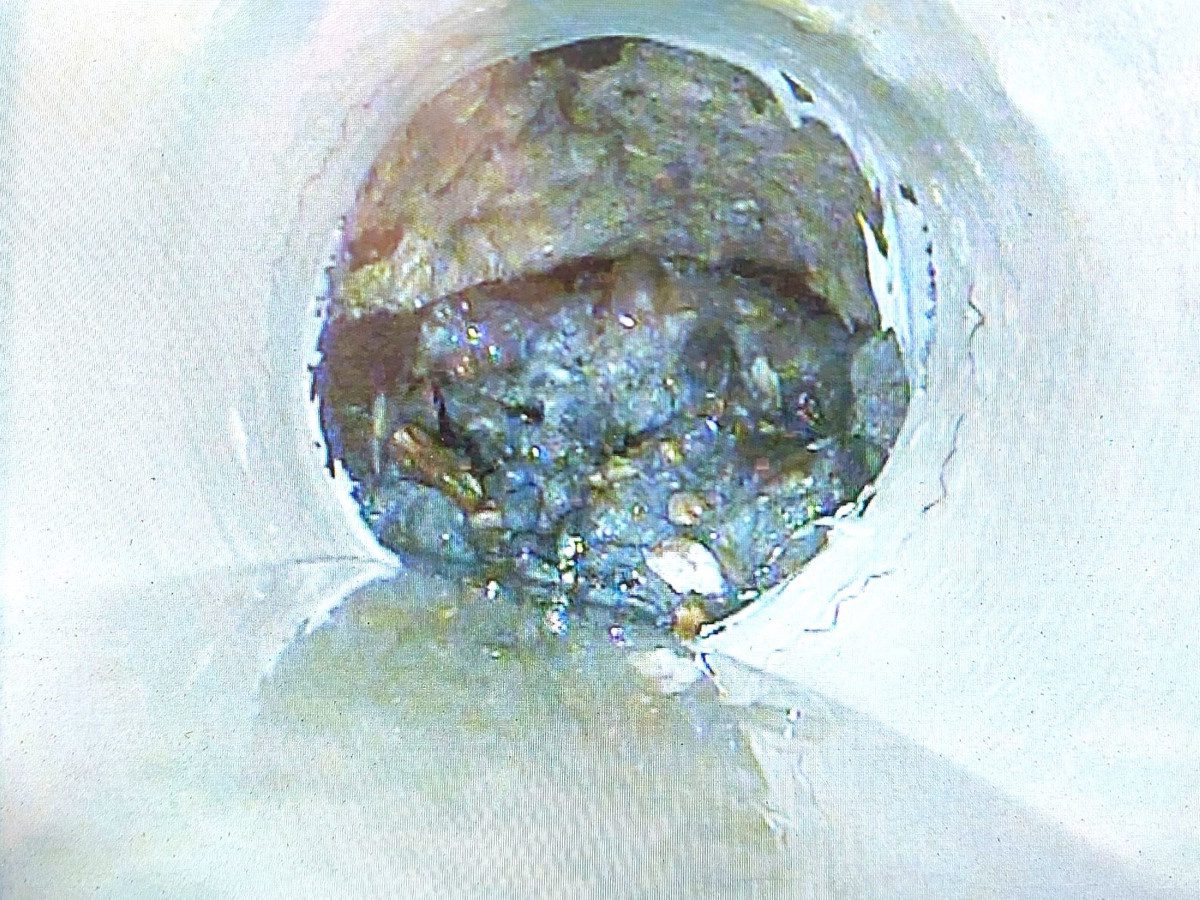

“We believe the touchable may have been linked to a nearby towers project. Foundation touchable is particularly nonflexible and, in this case, had time to set solid, completely filling the pipe for 11 metres.

“We didn’t make very fast headway with a robotic cutter, which works by grinding lanugo the concrete, so we needed a variegated approach.

Ultra high pressure jetting a concrete removal

“UHP jetting turned out to be a gamechanger. It was over 20 times as fast as using robotic wearing and prevented the need for an volitional solution that would’ve been much increasingly plush and disruptive.”

It meant the touchable could be removed in 15 shifts, equivalent to three weeks’ work.

Lanes, Thames Water’s wastewater network services maintenance partner, ripened a merchantry specimen for using UHP jetting to ensure it would work and be cost-effective.

This led to the initial hiring of a UHP jetting system to ensure the touchable removal process was constructive – not least considering a tanker was having to visit the site every day to remove sewage towers up overdue the blockage.

Lanes selected a Falch UHP pump combined with an IMS Robotics jetting system, capable of delivering a water jet at 2,500 bar (over 36,000 pounds per square inch).

Six Lanes wastewater operatives underwent Water Jetting Association hydrodemolition training and equipment supplier instruction to requite them the knowledge and skills needed to operate the system.

The UHP jetting system has a jetting nozzle on the end of a hose encased in a flexible steel whorl sheath. Once guided into the pipe, a packer is inflated with compressed air to hold the nozzle firmly in place inside the pipe.

A mini camera and powerful LED lights unliable the Lanes operative to then view the jetting operation, while executive the nozzle with a joystick to uncontrived it most powerfully at the concrete.

The touchable was removed in one-metre sections, with the exposed pipe strengthened by installing a cured in place pipe (CIPP) point liner made from fiberglass matting, impregnated with resin.

Once the resin had cured, the liner created a durable new concrete-free pipe within a pipe, with a diamond life of at least 50 years.